Spun Products

NuSpace has developed proprietary technology for the near-net spin-forming of precision components for various launch vehicle and satellite applications. NuSPace makes the best use of stock metal sheet and plate materials to reduce cost and lead times. The ability to spin to near-net shape reduces the amount of finish machining compared with forging or other forming technologies , further enhancing NuSpace’s cost and lead time advantage. NuSpace uses both conventional and CNC processes to produce high quality dome products ranging in diameter from 5 to 120 inches. Available dome materials include aluminum, titanium, stainless steel and high nickel alloys.

�

Spinning to 10 Feet Diameter

– 3 Spin Lathes,

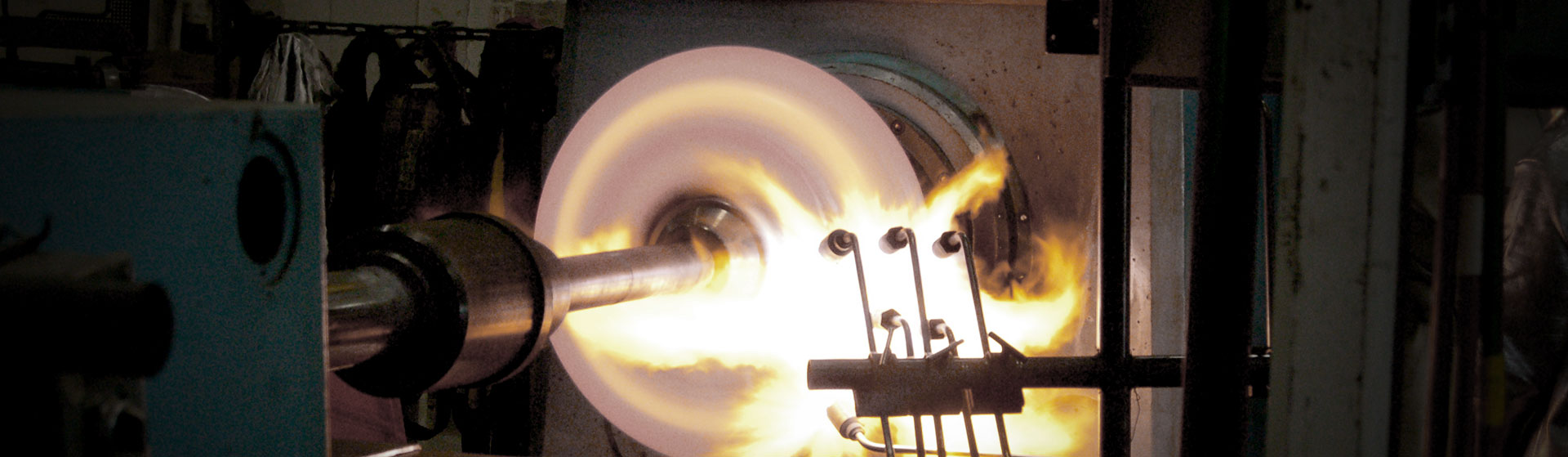

– CNC Hot Spinning