Design & Manufacturing Engineering

NuSpace has complete capability for the design-to specification of critical machined and welded spacecraft and aircraft assemblies and systems. By working with our customers from the beginning of a project NuSpace is able to provide valuable design-to-process input relative to manufacturing processes to be employed and validating design productivity.

Our highly skilled engineering and manufacturing team acts as an extension of our customer’s capabilities providing final design, manufacturing, quality control, installation, testing, documentation, and compliance with all other requirements as defined in the customer’s specification and Statement of Work. This means designs that include preparation and delivery of 3-D solid models of the final configuration, and preparation of manufacturing drawings and process documentation. Also included is the analysis to support all design, functional performance and service life requirements of the specification. As required, NuSpace can perform finite element analysis, fatigue analysis, and thermal analysis in development of designs using the most up-to-date analysis tools available. Additional analytical capabilities include failure modes and effects analysis and physics of failure analysis.

Engineering | Technical

• Engineers with Diverse Backgrounds and Capabilities

• Product Design and Performance Analysis

• Manufacturing Planning and Tool Design

• Weld Engineering

• CNC Programming

• Quality and Project Engineering

“State Of The Art” CAD/CAM

• CREO Solid Modeling for Design

• Pro-Manufacturing and CNC Programming

• SURFCAM Simulation

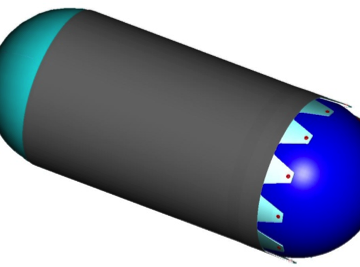

Propellant Management Device Analysis

• Negative G, Positive G and Low Gravity Fluid Dynamics

• Propellant Surface Tension and Contact Angle Effects

• Simulated Fluid Dynamics and Performance Modeling

• FLOW 3D CFD Software

Thermal Analysis

• Finite Analysistwareics and Performance Modeling Scripts

• Heat flow and temperature distributions using SINDA/G thermal analyzer program

• Shell radiation modeling

Mechanical Analysis

• MSC / Nastran FE shell modeling

• FEMAP and MSC / Patran

• Non-linear, stability and dynamic FE analysis

• Fracture mechanics and fatigue analysis to MIL-STD-1522A using NASGRO