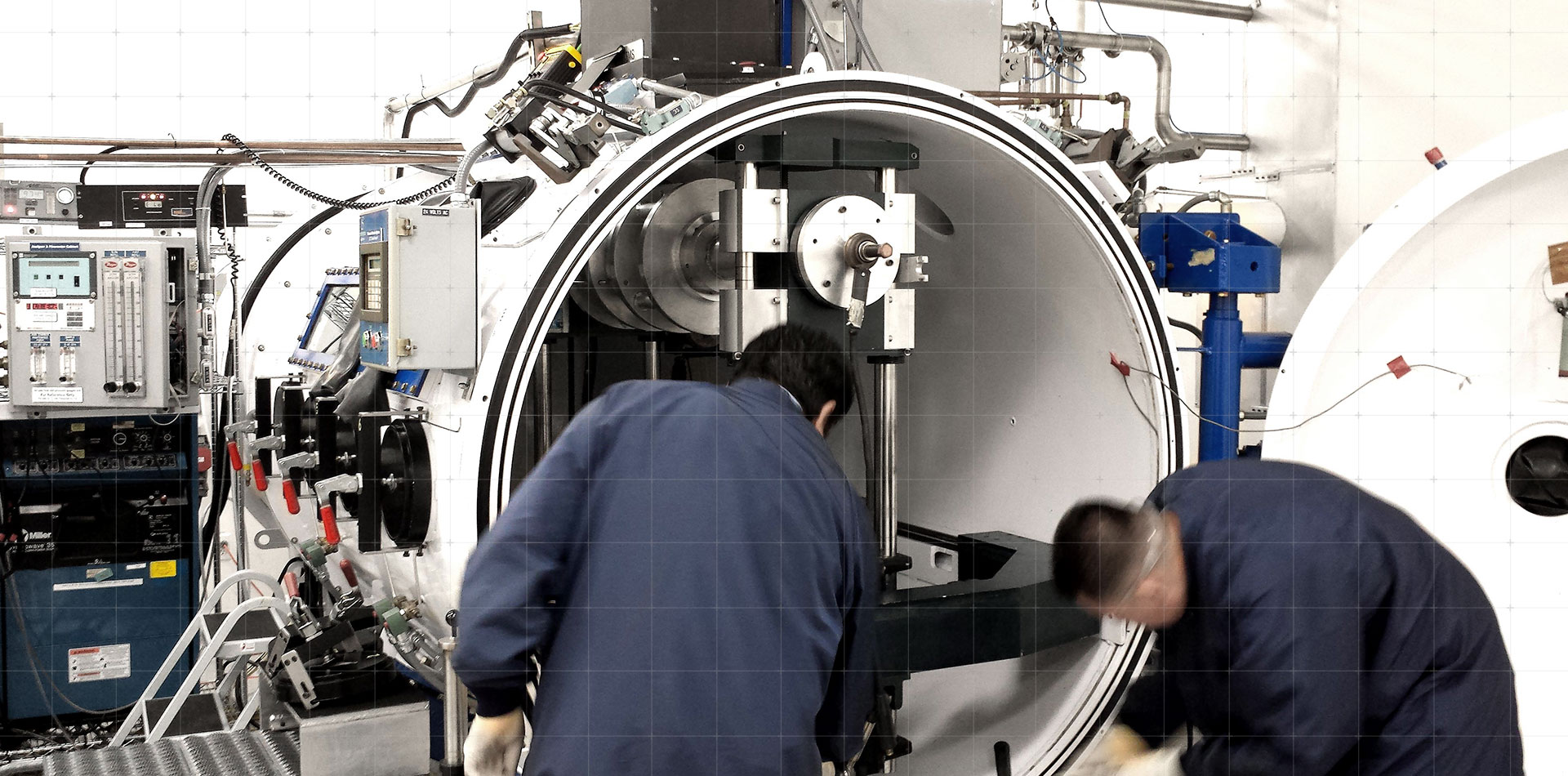

Assembly and Welding

NuSpace also provides state-of-the-art weld technologies, including Gas Tungsten Arc (GTA — often called TIG), Variable Polarity Plasma Arc (VPPA) and Plasma. Nuspace’s world class welding equipment and facilities include a “state of the art” class 10,000 clean room (ISO 7) that is specifically designed for ultra critical weld operations. The weld facilities include a large capacity, computer controlled welding chamber (60” X 120”). The chamber is fully instrumented with oxygen & dew point monitoring, circulating dry-train system to continuously remove moisture from atmosphere, and multiple glove ports for welding and set-up operations. Additional capabilities include certified welders and processes that meet ultra critical weld assembly requirements. In support of the welding operations is a fully functional cleaning process facility with capabilities to Level 100 requirements. This cleaning facility includes large capacity heated tanks with air-agitation for cleaning agents to support cleaning for welding, nondestructive testing, and heat treatment of parts. Precision cleaning of parts is performed inside a clean room using heated cleaning agents and ultrasonic agitation. All cleaning processes use heated D.I. water for rinsing and high purity argon for parts drying.

Non Destructive Evaluation

NuSpace provides a broad suite of inspection and test capabilities including visual inspection, fluorescent dye penetrant inspection (FPI), and radiographic inspection X-Ray). NuSpace FPI and X-Ray inspections are certified as Special NDE per NASA-STD-5009 for crack detection to sizes of 0.050” and .6T respectively to support manufacturing of thin-wall fracture-critical pressure vessels. Additional in-house testing

includes bubble point testing and leak detection using helium mass spectroscopy.

XRay Booth